Production Capabilities

One Stop Shop Capabilities

At JMTG, we specialize in creating top-quality toothbrushes through a meticulous four-step process: injection molding, handle decoration, tufting, and packing. From initial design to the finished product, our company handles every stage to deliver exceptional toothbrushes tailored to your needs.

Filament Specialist

We have advanced our bristle tufting technologies to cater to a range of preferences, from soft to ultrasoft. Our innovative approach allows for larger holes, enabling more bristles to be packed in, enhancing the brush's softness and overall feel.

Diverse Designs

Our handle concepts are continually evolving to meet diverse needs. We offer a variety of models, from slim tech heads and replaceable heads to reduce plastic waste, to handles made with eco-friendly materials like rice husks and hemp plastic.

High Degree Bristle Customization

Our bristle material sourcing is unmatched, drawing on over 40 years of industry expertise. We offer a wide range of bristles, from traditional charcoal to bamboo & himalayan salts, all complemented by our world-class tufting technologies and state-of-the-art machines capable of meeting every need.

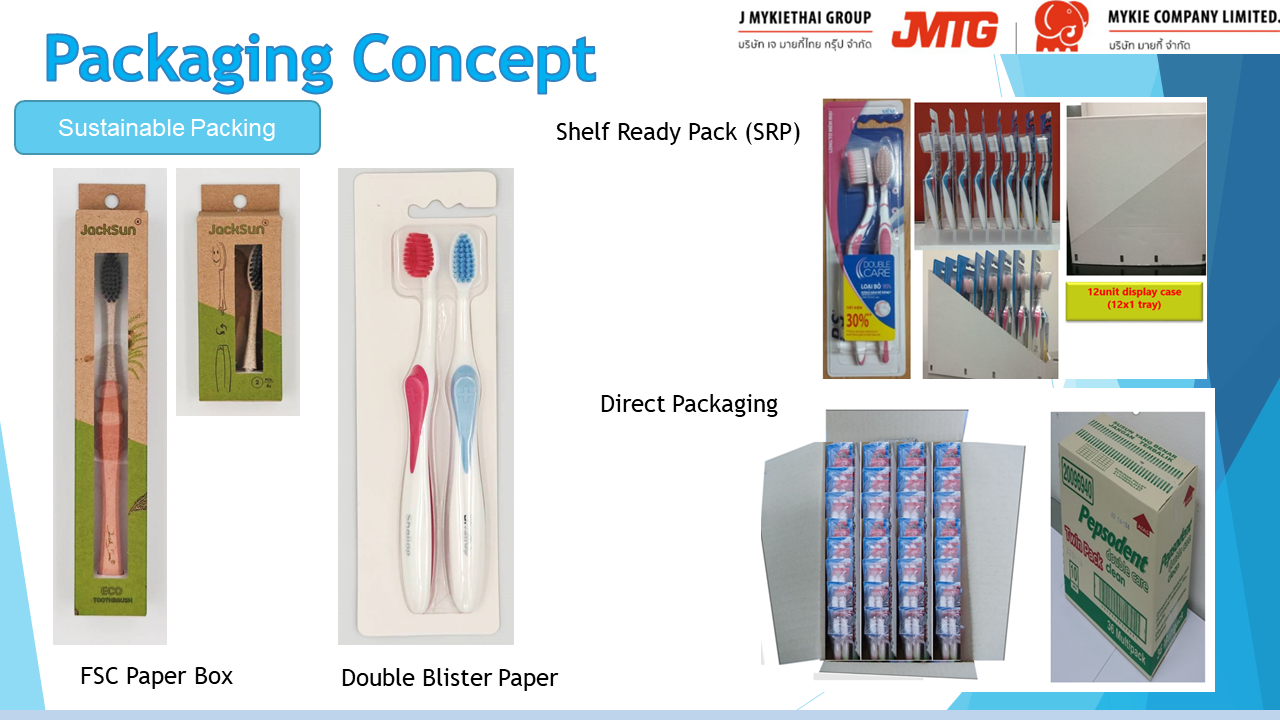

Flexible Packaging Technology

Our packaging technologies are top-notch and versatile. We offer innovative solutions like reverse blister packaging for dual-sided display, multibags, and display tubes, ensuring your products are presented perfectly every time.

Eco-Friendly and Shelf Ready Packaging Options

We are also committed to sustainability in every aspect, including packaging. We offer eco-friendly solutions such as recyclable cardboard packaging and convenient shelf-ready options for retailers. With our focus on environmental responsibility, your toothbrushes are not only high-quality but also planet-friendly from production to shelf.